Recent Innovations That Improved Efficiency in Manufacturing

The manufacturing industry relies on various technologies to remain efficient. Here are some recent trends that have improved efficiency in manufacturing.

Feb 27, 2025: Technology continues to redefine the manufacturing industry at an unprecedented pace. With efficiency at the core of modern production, recent innovations are helping manufacturers operate faster, smarter, and more cost-effectively than ever before. Discover recent innovations that improved efficiency in manufacturing and how these advances drive the industry forward.

1. Advanced Robotics and Automation

Robots have been used in manufacturing for decades, but today’s robots are smarter and more efficient than their predecessors. With advancements in robotics and automation, industries are seeing more seamless production lines and precision work. Collaborative robots, or “cobots,” are a prime example. Unlike traditional robots, cobots work alongside humans rather than replacing them, increasing safety and productivity.

Companies like Tesla use advanced robotics to streamline assembly in their Gigafactories, reducing production time and errors. This combination of automated efficiency and human interactive design ensures high-quality products at a fast rate.

2. 3D Printing in Mass Production

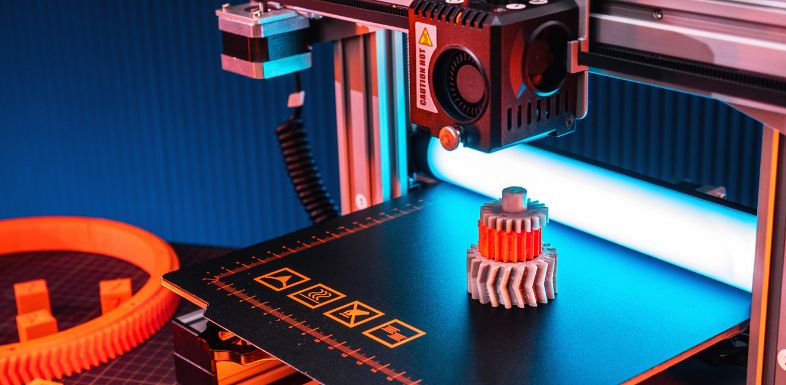

What started as a tool for rapid prototyping evolved into a powerful technology for full-scale manufacturing. 3D printing, also known as additive manufacturing, now enables companies to produce parts on demand, saving time and resources. One of the exciting developments lies in its use for prototyping.

As testing products is an important part of development, businesses are investing in 3D printers for easier prototyping and development. By cutting material waste and speeding up production timelines, 3D printing is a game-changer in industries ranging from aerospace to consumer goods.

3. Internet of Things (IoT) for Smart Factories

IoT is streamlining production by creating smart factories where machines, devices, and systems communicate seamlessly. By collecting real-time data from interconnected equipment, IoT enables manufacturers to monitor operations, detect inefficiencies, and prevent downtime. Adopting IoT solutions reduces equipment failures and increases cost savings, showcasing how smart manufacturing is the future.

4. Machine Learning and AI in Predictive Maintenance

Machine learning and artificial intelligence (AI) are giving manufacturers a crystal ball for predicting potential failures before they occur. Predictive maintenance powered by AI analyzes historical data to forecast when equipment might break down, allowing businesses to schedule maintenance proactively. This approach not only minimizes costly downtime but also extends the lifespan of vital machinery.

5. Laser Cutting

Precision is critical in manufacturing, and that’s where laser cutting comes in. Methods laser tube cutting increase production efficiency by speeding up the process of cutting materials to make products.

This innovation uses high-powered lasers to cut materials with incredible accuracy, whether it’s sheet metal for automobiles or fabrics for clothing. The improved accuracy reduces waste by using materials efficiently.

In Conclusion

The manufacturing industry is no stranger to innovation. From automated robots to AI-driven predictive maintenance, many recent innovations have improved manufacturing with new ways to create. Staying informed about these advancements isn’t just exciting—it’s essential for understanding where industries are headed.

To stay ahead of the curve, explore more ways technology can disrupt and enhance traditional manufacturing. Keep an eye out for what’s next—because the future is being built one innovation at a time.